Unique Feature Reduces Irretrievable Instrument Separation

Dentists using tapered (nickel titanium (NiTi) rotary instruments eventually learn an extensive list of tricks to avoid instrument breakage: run it at the proper speed; use a torque-controlled motor; avoid severely curved canals; clear the flutes frequently; avoid too much engagement along the length of the blade; and do not push too hard, force the instrument where it does not want to go, overuse the instrument, or try to cut too much dentin at one time. Nonetheless, breakage still occurs.

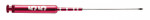

When designing the new LightSpeedLSX instrument (Figure 1) the shortcomings of tapered rotary instruments were well known. One of our goals was to practically eliminate the dentist’s fear of separation during rotary instrumentation. Thus, several unique design features were incorporated into the new LightSpeedLSX, the most significant being the SAFETY RELEASE feature, which causes the shaft of the LightSpeedLSX to twist up or separate completely from the handle when too much stress is applied (Figure 2). When a safety release occurs, the remaining fragment is easily and quickly retrieved because the fragment is approximately 21 mm in length; therefore, the end of the remaining fragment is at or above the level of the canal orifice. With its small tips and excellent grippingpower, our MicroForceps make retrieving the separated fragment a non-issue—simple, easy, and quick.

Creighton Dental School has been teaching their dental students the LightSpeed technique for roughly 10 years now. A study conducted with the previous version of LightSpeed (LS1) showed aremarkably low irretrievable breakage rate of 1.3%.1

In 2005, Creighton converted to LightSpeedLSX and continued monitoring instrument breakage. Recently, Creighton shared their data with us. Out of 3,100 canals treated by junior and senior dental students using the LightSpeedLSX with the new SAFETY RELEASE feature, the breakage rate dropped from 1.3% to only 0.37%—a reduction of approximately 72%.

This figure is even more significant when compared to results from studies completed with tapered NiTi rotaries. One such study revealed a much higher breakage rate of 5% when 7,159 instruments of 8 different brands were examined.2

A study conducted at UCLA in 2006 documented the physical properties of LightSpeedLSX. Intentionally fracturing LightSpeedLSX and tapered NiTi instruments by holding their tips and twisting them apart, results revealed that in 100% of the cases, the SAFETY RELEASE feature of the LightSpeedLSX worked as designed. Comparatively, all of the tapered instruments broke near the tip where retrieval of the remaining fragment would be highly unlikely (Figure 3).

This makes sense. An instrument will tend to separate at its weakest point and the weakest part of a tapered instrument is near its tip, whereas the weakest part of the LightSpeedLSX instrument is at the bond between the shaft and the handle. We were able to “dial-in” the bond strength between the shaft and handle. The trick was to find a way to ensure that the shaft would pull loose from the handle before it could fail from too much twisting force.

Although the breakage rate is very low with LightSpeedLSX, preventingbreakage boils down to keeping a few things under control. Pushing too hardand too fast is themost common mistake made by beginners.Fortunately, the safety release featurewill prevent irretrievable separations from this error most of the time. Always remember to advance slowlyand let the instrument do the work.

Secondly, do not overuse the instrument. It simply wears out from the fatigue caused by the spinning action of the shaft in a curved canal. The bond between the shaft and handle can also weaken with repeated sterilizations. This may cause a SAFETY RELEASE to occur at a much lower torque level than when the instrument is new. You should therefore limit use to no more than four times in normal canals and single-use in severely curved canals.

Third, running the instrument at too high or too low a handpiece speed can also lead to problems. When used at high speed, fatigue occurs more quickly. When used at a low speed, the cutting efficiency is greatly diminished, which leads to higher twisting forces and typically causes the clinician to unintentionally push much harder. Testing revealed that 2,500 rpm is the optimal speed for LightSpeedLSX.

Finally, instrument breakage can also be a result of poor access. If the instrument must bend before its tip reaches the mid-root, refine the access further to eliminate the bend. See the StraightLine™ Access Technique Guide for details.

While irretrievable breakage has not yet been completely eliminated,0.37% is quite remarkable.But the news gets even better. The same Creighton study showed that 75% ofirretrievable instrument fragments could be bypassed and filled to length.This result is a factor of the unique LightSpeedLSX spade-shaped blade that can leave ample room for bypassing on either side. This means that the chances ofleaving a short fragment in the root without being able to bypass is approximately 1 in 1,000.

Some call it “safety first,” but at Discus we call it “reduced separation anxiety.”

References

1. Knowles K, Hammond N, Biggs S, Ibarrola J.Incidence of instrument separation using LightSpeed rotary instruments. J Endod.2006;32(1):14-16.

2. Parashos P, Gordon I, Messer H. Factors influencing defects of rotary nickel-titanium endodontic instruments after clinical use. J Endod.2004;30(10):722-725.

For more information, contact:

Discus Dental

Phone: 800-422-9448

Web: www.discusdental.com/endo

The preceding material was provided by the manufacturer. The statements and opinions contained therein are solely those of the manufacturer and not of the editors, publisher, orthe Editorial Board of Inside Dentistry. The preceding is not a warranty, endorsement, or approval for the aforementioned products orservices or their effectiveness, quality, orsafety on the part of Inside Dentistry or AEGIS Communications. The publisher disclaims responsibilityfor any injury to persons or property resulting from any ideas or productsreferred to in the precedingmaterial.

About the Author

Steven Senia, BSIE, MBA

Executive Director of New Product Development

Discus Dental, LLC