Digital Partial Design and Manufacturing

Using 3D printing technology to fabricate removable partial denture frameworks.

By Robert Kreyer, Jr., CDT

As prosthetic dental laboratory technology evolves in the digital world, technicians must learn how to use these new manufacturing processes. Such technology will help them improve their prosthetic quality, communication, efficiency, and productivity. Three-dimensional digital printing technology and other digital fabrication processes will not replace the experienced and educated dental technologist, because knowledge of biomechanical principles of removable partial denture frameworks is still essential to a successful case. Because digital evolutionary technologies are changing so fast, the author thought it best to collaborate on this article with other technicians and manufacturers with experience in and knowledge about with the various 3D printing technologies on the market. The technology presented from 3Shape and Envisiontec is used at the author’s laboratory, MicroDental. Because MicroDental does not use the 3D Systems inkjet printing system, which is another proven way to print partial denture patterns, the author reached out to CadBlu Dental for information on the use of that system. He also asked Ann Schmitt from CMP Industries for her expertise on investing 3D-printed patterns using Microfire investment (CMP Industries, www.cmpindustries.com). In addition, Scott Udell provided comparative information from a broad spectrum of dental laboratories using Labtrac case management software (Labtrac Solutions, www.labtrac.com). Udell’s information compares time studies using conventional casting techniques versus aided design and manufacturing techniques (See Chart).

In his article, “Digitally Designed RPD Framework,” in the March 2012 issue of Inside Dental Technology, the author demonstrated what can be done using the 3Shape CAD Software (www.3shape.com) As discussed in the the article, he designed maxillary

and mandibular frameworks using the 3Shape Partial Design System and printed them in wax resin using two different technologies. One set was printed with the Envisiontec Perfactory Ultra2 (www.envisiontec.com) and the other set was printed with 3D Systems Projet 3000 inkjet system (www.printin3d.com).

Scan, Design, Print

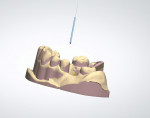

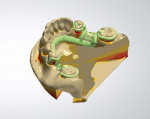

This was not a study on the two technologies but rather a laboratory comparison of techniques, materials, and finished partial castings. To begin the digital fabrication process, the maxillary and mandibular models were scanned, then designed using the 3Shape partial denture design system (Figure 1 through Figure 3).

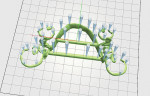

One set of design file data was transmitted to the 3D inkjet system, and the other set of files was printed using the Envisiontec Ultra2 perfactory system. Figure 4 through Figure 8 demonstrate the removable partial denture framework digital design using the perfactory spruing technique. In Figure 9, the final printed resin patterns are shown attached to sprues and print platform. The resin sprues from the Envisiontec printing process are easily removed, taking an average of 3 minutes per partial to cut and smooth the sprues.

In Figure 10 and Figure 11, a printed partial pattern from the 3D Systems inkjet printing technology is shown. The white wax sprue system is very different than that from Envisiontec and is eliminated in minutes by soaking in corn oil at 81°F.

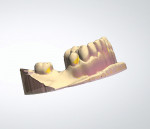

Figure 12 shows the Envisontec perfactory maxillary partial pattern after the sprues have been removed and smoothed, leaving the support bar for spruing to invest and then cast. Figure 13 through Figure 15 are the printed maxillary and mandibular partials from the 3D Systems inkjet technology. Of note is the great detail in the external and internal finish lines with both printing systems.

When conventionally spruing a partial framework designed, duplicated, and hand waxed on a refractory cast and cast in metal using conventional partial casting techniques, only one framework at a time can be invested and cast. In other words, using a burn-out furnace that holds 10 rings, only 10 frameworks can be cast during a single burn-out cycle. Using 3D printing technology, four partial pattern frameworks can be sprued and invested in a single ring, making it possible to cast up to 40 frameworks per burn-out cycle using a 10-ring capacity furnace (Figure 16). Figure 17 shows four 3D printed partial framework patterns sprued and placed in a ring ready for investing. In Figure 18, the patterns are invested using the Microfire investment.

Conclusion

Dental laboratory technology is currently in a period of consolidation with a decreasing number of dental laboratories offset by an increasing demand for removable partial denture prosthetics. Having the ability to manufacture digital partial frameworks will increase daily productivity and profitability in the laboratory. The computer-aided design and manufacturing technology for prosthetic dentistry is in its infancy and will continue to evolve in the coming months and years. As in life and business, it is necessary to always plan for the future and change plans according to business needs and demands. The dental profession and industry is rapidly changing from year to year. Dental technicians and laboratory owners must evolve and change with the times as well.

To read the author’s first article on “Digitally Designed RPD Framework,” please visit: dentalaegis.com/go/idt45

About the Author

Robert Kreyer, CDT

Director of Removable Prosthodontics

Microdental/DTI

Dublin, California