3D Printing and Laser Sintering Technologies

Additive technologies are finding increased uses in the dental laboratory industry.

Technology and equipment from other industries have regularly been adapted for use in the dental industry. Scanners, both model and intraoral, have their roots in other markets. Most of the computer-aided manufacturing (CAM) milling systems in use today in dental laboratory production processes came from other industries. Thus, it should come as no surprise that the 3D printing and rapid prototyping technologies used in general manufacturing have joined CAD/CAM milling and scanning as an emerging and new technology in dentistry.

CAM milling technology is a familiar process to dentistry. Often referred to as a subtractive process, milling involves taking a block of material and cutting away everything that is not necessary until the final part emerges. In contrast, 3D printing technology is an additive process, one that involves adding material layer by layer to build the final product.

Currently, 3D printing technology, or "additive manufacturing" as it is being called, is used to provide a number of products in the dental industry. Most common are wax patterns for fixed prosthodontics and models fabricated from intraoral or impression scans. However, popularity is gaining for orthodontics and removable prosthodontics.

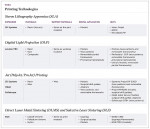

There are basically four different 3D printing technologies being used in the dental industry today: stereo-lithography apparatus (SLA), digital light projection (DLP), Jet, and direct laser metal sintering (DLMS). Each system varies in the materials available, how those materials are solidified, and how they can be used.

Support Material and Build Envelope

Each additive manufacturing system features a working platform that is typically lowered each time a layer is printed. The final part must be physically separate from the platform to facilitate easy removal. The entire length and width of the part also must be supported; otherwise, cantilevered sections would collapse. Supports may be vertical rods made of the final part material, or a solid section of a special wax. Depending on the printing technology used, the support material is cut off, or rinsed/washed off after the part has been printed.

Each 3D printing system has a specific build envelope, or part size limitation, upon which the printing takes place. The greater the length, width, and height of the build envelope, the more parts that can be printed during a job.

Project Set-up

Special CAM software is used to import a computer-assisted design (CAD) file, usually supplied in STL or SLC format, from a scanner or CAD software. The CAM software slices the parts into discrete horizontal layers, anywhere from 13 µm to 100 µm in thickness. Some CAM software programs require manual identification of support material locations, while others will place supports automatically. Sometimes a second program is used to manage the jobs the printer is running.

Build Time

Build time is the time required to print a project from start to finish. It is a function of the height of the parts being produced and the layer thickness of the parts. The taller the parts, and the more layers that must be printed, the longer the project will take. Most systems offer a high-resolution mode with the smallest possible layer thickness, or a high-speed mode where the layers are fewer, but thicker. There is always a compromise between layer resolution and build time. Certain technologies, such as SLA and DLMS, where the laser traces each part individually may take longer than DLP technology, where a complete layer including all of the parts is projected at once onto the build platform, or Jet technology, where sections of parts are printed with each pass of the print head.

Stereo Lithography Apparatus (SLA)

Stereo Lithography Apparatus (SLA) 3D printing uses a UV-sensitive liquid resin as the working material. A UV-laser is projected on and moves across the reservoir of the resin build material, illuminating and hardening the liquid resin only in the areas where the part is being printed. If multiple parts are being printed, each part is traced on the resin by the laser. The platform holding the part or parts lowers after each layer is printed, and a wiper blade spreads more build material uniformly across the working space. The UV laser makes another pass, tracing the outline of the next layer for each part in the print job. The process is repeated layer by layer until the job is complete. SLA technology allows for varying the layer thickness throughout the printing process. Some layers can be 100 µm thick where accuracy is not critical and then dialed to 50 µm or less when greater accuracy is required.

SLA printing technology is available with a wide variety of materials. A 25-µm to 50-µm layer thickness is achievable with excellent accuracy and good surface finish. SLA typically has slower build times due to the laser outline of each part. Post-print processing may require cutting the final part from the support material, removal of excess material, and the parts placed in a UV oven for final curing.

Digital Light Projection (DLP)

DLP 3D printing is in some ways very similar to SLA. The working material is also UV- and visible-light sensitive and held in a reservoir. A wiper blade spreads material uniformly across the build platform after each layer is printed. However, instead of tracing the outline of each part with a laser, DLP takes advantage of the same technology used in certain television sets and presentation projectors to illuminate the outline of all of the parts simultaneously. The printed material is cured using a lamp or LED light source depending on printer model.

Typical vertical resolution is 13 µm to 50 µm with very good accuracy and excellent surface finish. Post-print processing involves removal of support material by rinsing.

Jet (PolyJet/ProJet) Printing

3D jet printing is just what it sounds like, a more sophisticated big brother of the inkjet printer. Instead of ink being jetted or sprayed onto paper in a single layer, a resin or wax is jetted onto support material, and then onto previously sprayed layers until the part begins to take on depth and shape (Figure 1).

3D Jet printers may have a single print head like a computer printer, or they may have multiple heads to cover the width of the working platform. Either the print head moves across the working platform, or the platform moves back and forth under stationary print head(s). The 3D Systems and Objet printers use a UV lamp or a light source to harden the resin or wax after each layer is jetted. The Solidscape printer jets a heated wax that cold-cures in place and does not require exposure to a UV light source.

Typical layer thickness ranges from 16 µm to 50 µm with excellent accuracy and surface finish. Post-printing processing is simply removal of the support material, usually with a water or oil bath and simple rinsing. Most systems have self-cleaning print heads, so no user intervention is required. The curing light source, if necessary, is usually a Xenon lamp with a long service life.

Direct Laser Metal Sintering (DLMS) and Selective Laser Sintering (SLS)

DLMS and SLS are similar technologies that involve a powder-based working material. DLMS uses a metal powder and SLS typically uses a plastic powder. The powder is spread across the working platform. A laser traces the outline of each part being printed, fusing (DLMS) or melting (SLS) the powder to the layer below it. The platform is lowered, a new layer of material is spread across the platform and the process repeated until the print job is complete.

DLMS technology has traditionally only been available for printing non-precious metals. Recently, Argen has developed its own materials and techniques for the EOS machine that allows them to provide both non-precious and noble metal copings. Post-print processing requires cutting off the support material.

Conclusion

Additive manufacturing technology in the dental industry is gaining popularity. Materials and printing techniques continue to improve as manufacturers receive feedback on what is needed in terms of performance. Available materials are often manufacturer- and, sometimes, machine-specific. Be sure to check with the manufacturer on available materials for any printer under consideration for purchase. Most manufacturers are more than willing to send sample parts if they are sent an STL file to work with. It is a great way to assess the accuracy, finish, and workability of the material produced from the printer.

3D printing technology has been used for years for rapid prototyping (RP). Equipment manufacturers often want to create a prototype part without investing in expensive tooling. Typical use for RP technology has been same-part, small-volume production, with very good to excellent accuracy. The dental industry requires custom-part, single-unit production, with excellent accuracy. The volume of single-unit production in the dental industry is unlike anything the RP industry has encountered before. Dentistry is quite possibly the ultimate industry for RP technology to move into. Additive manufacturing equipment makers and material suppliers for these printers are already taking notice.

About the Author

Chris Brown is the manager of the Apex Dental Milling in Ann Arbor, Michigan.